When I get around to scanning my hand drawn plans for my greenhouse you will see that I intended a 6 foot wide, 10 foot long 8 foot high frame with ribs made of 10 foot pipe lengths. This planning was well intentioned but the resulting greenhouse was a monster. I know because I loosely assembled it and was awed by its size. I adjusted mid-course in a few areas and now have a more modest 5 x 10* x 6 high with 8 foot ribs. Let me provide some sizing guidance and tell you about my experience working with PVC.

*10 feet actually became 11 feet which I explain below.Watch your greenhouse "grow"Whatever the initial dimensions of your pipe lengths are cut to, expect them to grow a little as you assemble them. The reason is that each tim you cut a pipe to insert a fitting you are adding between 1 and 2 inches.

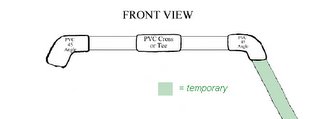

In my case, I started with 10 ft long 1 inch PVC for the long base pipes. I need to cut those 10 foots to insert the T--shape pipe fitting where the ribs attached at the base. Each of the six T-pipe fitting is 2 1/2 inches long. No matter how hard you try to shove the ends of the cut pipe into the pipe fitting you'll have difficulty getting them inserted flush. In addition, there is at least 3/4 inch of space in the middle of the T to accommodate the rib attachment. So, in my case, my long 10- foot base pipe was almost 11 feet long.

Square Structure SizingI used 1 inch PVC for the square structure. When shopping for your PVC pipe grab two different 10 foot long piece: 1-3/4 inch and 1-1 inch. You'll notice the 3/4 inch bends and drops and the 1 inch basically holds its form. It was the rigidity of the 1 inch that drove me in that direction for the square structure. If you are going to have any dimension in your structure greater than 10 feet, I'd recommend upgrading above the 1 inch. This will add weight and dollars to your project so you may want to keep it to 10 ft. or less.

Additionally, consider whether you want to hang baskets from square frame. If so, you can upgrade the PVC pipe above 1 inch, add vertical supports half way down the 10 foot pipe, or plan to run galvanized electrical metal tubing inside your PVC for greater stability.

Curvature and length of the ribsI used 3/4 inch PVC for the ribs. This seemed just flexible enough to bend around the square 1 inch pipe frame while still solid enough for a reliable structure. The 1 inch pipe is firm enough to hold mostly square and not to bow while 3/4 inch pipe is bent around it. However, where the ribs meet the square structure is a stress point . You need the ribs to be about 2 feet longer than the height of the square structure. If they are less the square structure will bow and curve under the ribs.

Ribs spacingSpace your ribs at about 2 feet apart. This should give the proper amount of support when it is time to add the exterior sheeting. If you cut lengths of pipe at 2 ft and add T fittings the spacing will be a bit over 2 ft but, in the end, it will be fine.

PVC is not an exact science

I'd like to close the sizing section with the notion that PVC was not made for this kind of contruction. When you start to fit you pipes and fitting together variances will be introduced. One pipe inserts 3/4 of inch into the fitting but anoth 5/8 of an inch. A T fitting for a one inch pipe adds 2 inches of length but a T fittings for a 3/4 inch pipe add less. In the end the dimensions change and grow as you assemble no matter how well you plan. The good news is that PVC is flexible...You should be too!!!

Tags: greenhouse, pvc, roof deck

Reassemble the base with T-fittings

Reassemble the base with T-fittings